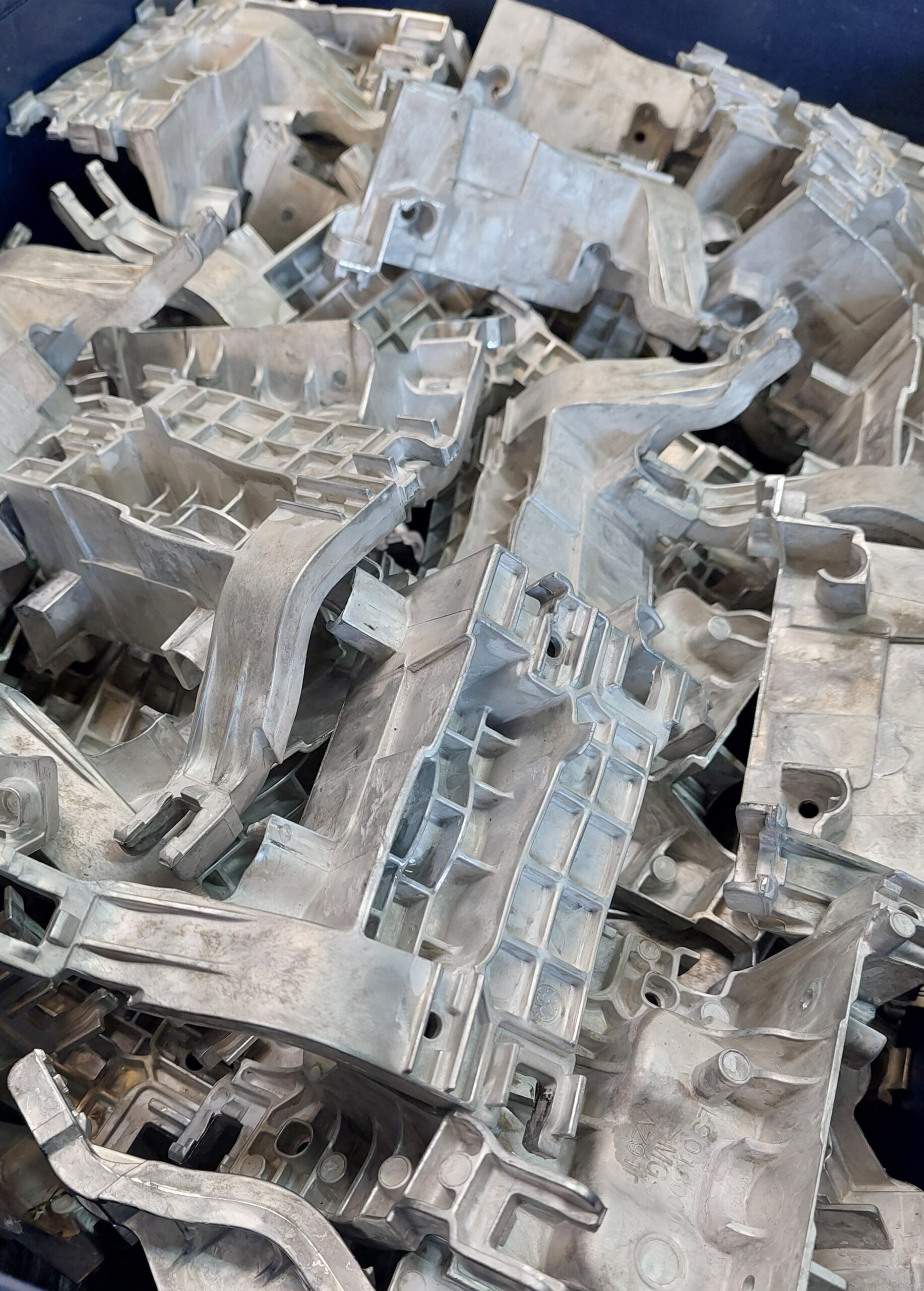

Magnesium, the lightest injected metal

in the world.

ID Casting manufactures parts made of AZ91D magnesium alloy which is 33% lighter than aluminium and 3x stronger than thermoplastics.

Our hot-chamber transformation process uses less energy than the cold-chamber process, making production costs more competitive.

Properties and benefits of Magnesium

Magnesium has a melting point of 650 degrees Celsius and offers a wide range of properties: mechanical strength, fluidity enabling complex shapes to be obtained, damping capacity, electromagnetic protection and suitability for surface treatments. Magnesium offers an excellent strength-to-weight ratio and is the metal of choice for customers looking for lightness without sacrificing rigidity.

- 33% lighter than aluminium

- Excellent strength to weight ratio

- Thin walls and dimensional accuracy

- Good vibration damping capacity

- Tool life ≥ 400,000 injections

- Fluidity: precise creation of complex shapes

- Electromagnetic shielding

- Temperature resistance

- Recyclability

A particularly useful alloy

for use in parts for the automotive, electronics, aerospace, rail, multimedia, power tools and sports sectors…

Discover also

ZAMAK

R&D

FOUNDRY

PRODUCTION