ID Casting, a sustainable development ethic

Respect for people and the environment are key priorities for the ID Casting group.

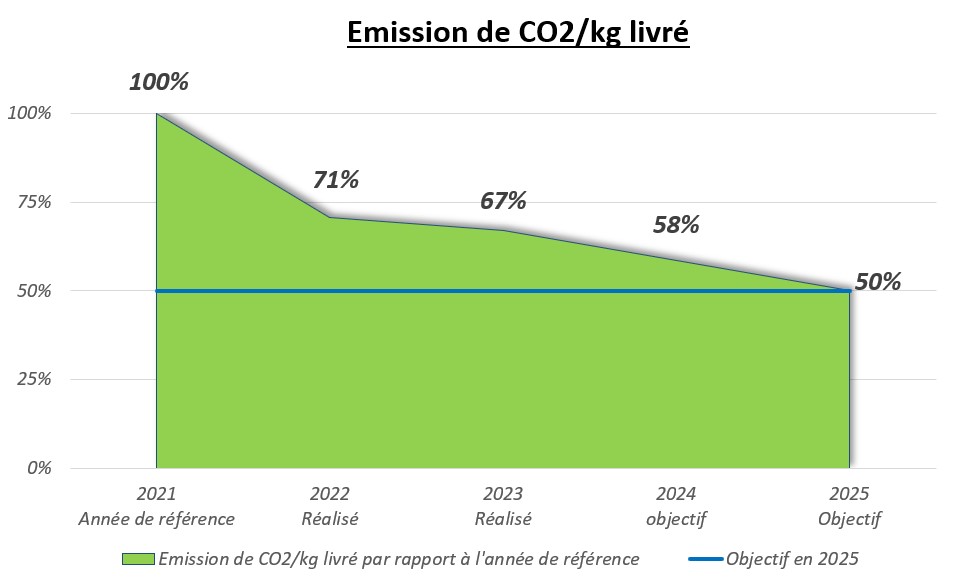

Our aim is to reduce our CO2 emissions by 50% by 2025.

A meaningful commitment

to the environment

To offer our customers technical solutions based on zinc and magnesium alloys with characteristics that limit their impact on the environment : recyclability without loss of mechanical properties, fluidity that optimises shapes and mass, limiting energy consumption and finishing operations. Whether it’s product eco-design, staff training or reducing environmental impact, the Group is committed to an environmental charter. With the eco-design requirements of today’s global industries, diecasting remains a model of sustainable development, thanks to its low energy consumption.

A policy

In constant improvement

ID Casting is committed to respecting the environment in a sustainable way, and is a member of a number of environment-related associations, including ECOVADIS, a specialised CSR platform that enables us to assess our CSR performance as a supplier in order to understand and improve our social and environmental practices.

The EcoVadis rating looks at a broad spectrum of non-financial management systems, in particular their impact on the following themes: Environment, Social & Human Rights, Ethics and Responsible Purchasing. Each company is assessed on key issues according to its size, location and sector of activity.

As an ambassador for innovation, always on the lookout for creative solutions that are consistent with the environment, ID Casting is a member of Expérience Zamak and the IMA (International Magnesium Association). These associations bring together foundries, alloy producers and recyclers, machine manufacturers and industrial equipment suppliers, and users, with the aim of promoting zinc and magnesium alloys.

The global standard for CSR assessments

Reducing our CO2 emissions

To meet environmental challenges, ID Casting has introduced an energy-saving plan.

The group began by working on its gas consumption (building heating systems) by installing a system that recovers the heat dissipated by the air compressors and by lowering the set temperature in the offices to 19°C. We are now continuing to optimise the electrical efficiency of our processes (modularity of compressors according to use; maintenance of the air network; insulation of furnaces; transition to LED technology; adaptation of opening hours according to workload)

These efforts will be rewarded by a 33% reduction in our CO2 emissions per kilogram of metal delivered in 2023. ID Casting’s ambition is to reduce its carbon footprint by 50% by 2025.