Magnesium alloy,

AZ91D

4

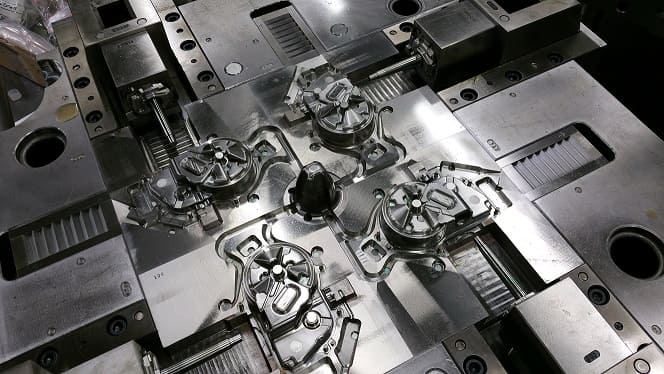

hot chamber presses

robotics

From 200T to 315T

in power

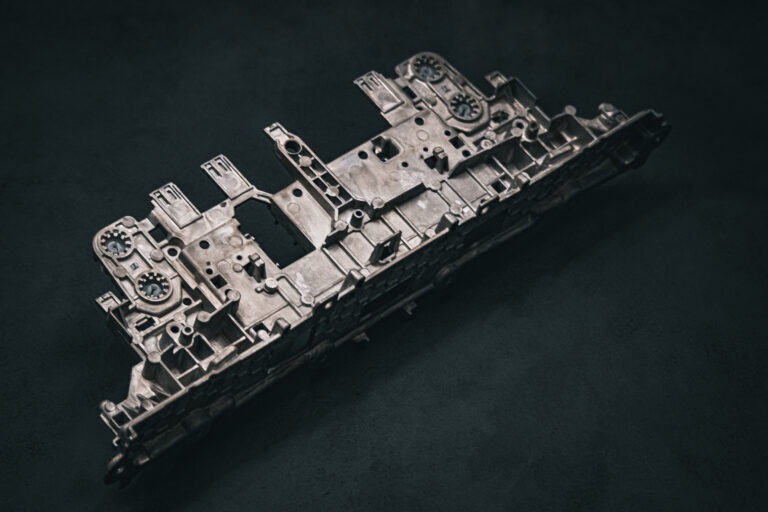

Parts ranging from

less than 40 grams to 600 grams

Combination of

lightness and rigidity

Mainly composed of magnesium, zinc, aluminium and manganese, magnesium alloys are the best-performing metal, combining lightness and rigidity.

It is the most suitable material when you are looking to reduce weight without compromising overall strength. Its vibration-damping capability is also beneficial in applications where the internal forces of high-speed components need to be reduced. ID Casting has a high-performance fleet of machines enabling it to cover the quantitative needs of its customers in the design of parts, with 4 robotised presses for magnesium injection. Our magnesium injection moulding machines offer a clamping force of 200 to 315 tonnes, enabling the manufacture of parts weighing from less than 20 to 600 grams.