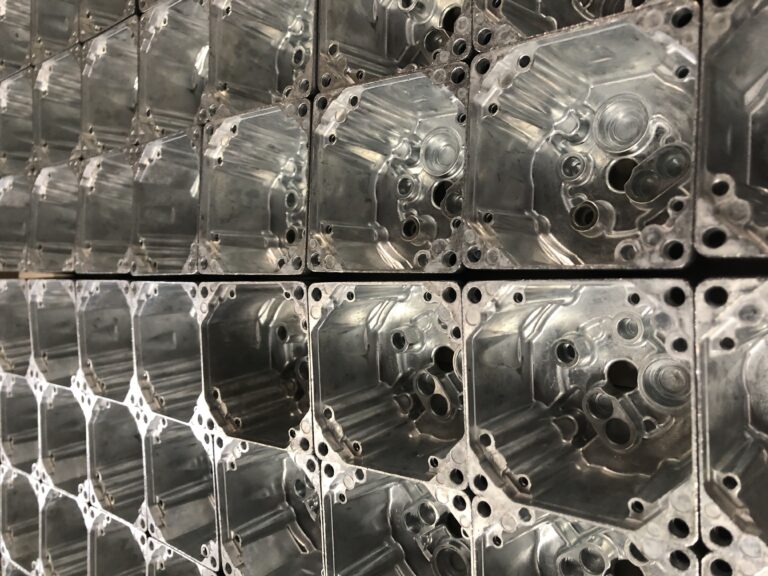

Our certifications are a guarantee of quality.

Entrusting your projects to ID Casting is a guarantee of serious, high-quality, rigorous work, as demonstrated by our certifications.

Our certifications

Every ID Casting Group site that delivers parts is ISO 9001 and IATF 16949 certified. This approach ensures that our customers are on familiar ground and that our sites have quality systems that meet international standards and are structured to meet their own quality system requirements.

Our Terms and Conditions

Controlled processes

The quality objectives of each of our sites are tailored to the type of customer delivered, with the aim of achieving “0” defects and “0” recurrence of incidents.

Fast, reliable processing of incidents in the form of 8Ds, where possible using coded pins and POKA YOKE on as many interfaces as possible.

In order to anticipate the occurrence and non-detection of incidents, ID Casting systematically works with its customers on process FMEAs.

To meet our objectives on a daily basis, we use the following quality tools: self-checking, metrology on 3D machines, camera checks, Poka Yoke, profile projector, pressure, density, rupture and tightness checks, statistical monitoring: 8D and QRQC methods and analyses.

Calling on ID Casting is the guarantee to have

know-how and interpersonal skills at your side.